Acrylic Liquid Motion Bubble Timer Toy Manufacturers

For ten years, we have specialized in the research and development of plastic handicrafts.

Research and development, production and sales all in one.

The factory covers an area of 6,000 square meters

Employs more than 200 people

And has several well-equipped production lines, with a monthly production capacity of 80,000 sets.

The main products are: acrylic oiled products, novelty toys, gifts and premiums.

We have a wide range of products, new styles and excellent quality.

We sincerely welcome inquiries from new and old customers.

Our Revolutionary Products

Sensory Fidget Toys Bubble Pens

Liquid Motion Bubbler Toy

volcanic eruption hourglass

Activity Liquid Motion Timer

Liquid Motion Bubble Keychain

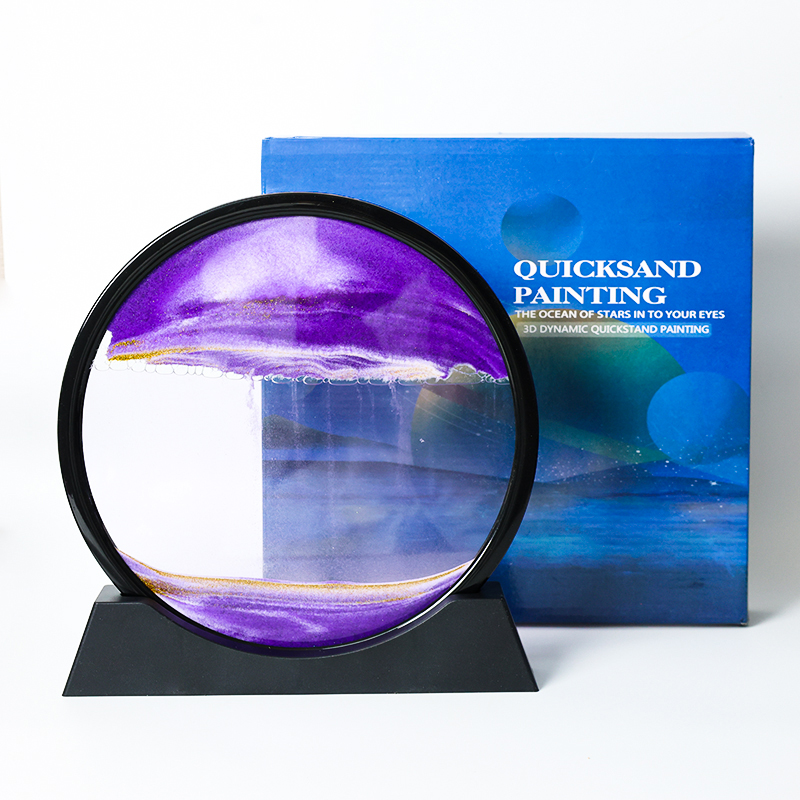

3D Dynamic Sand Art Frame

Liquid Timer Fidget sensory

Custom Liquid Bubbler Timer

Diamond Drip Tape 3D Cartoon

Small Size Hourglass

Sensory Toy For Relaxation

Custom Good QualityFactory Directly Sensory Toys

Sensory Fidget Tubes, Calming Toys for Kids, Occupational Therapy Toys, Play Therapy, Stress Relief Toy, Comfort Items for Anxiety, Calm Down Corner Supplies (Set of 4)

SOCIAL EMOTIONAL LEARNING ACTIVITIES: Teach kids to sooth themselves with hands-on calming toys for kids that help build social emotional skills by providing cues and physical objects to deal with big emotions, without the strains that come with screens.

QUIET TIME ACTIVITIES FOR KIDS: Each set of sensory tubes comes with 1 calming sensory glitter tube, 1 fantastic fidget tube, 1 magical reverse hourglass, and 1 soothing gravity spinner.

GREAT FIDGET THERAPY TOYS: Our mesmerizing sensory bottles are perfect as occupational therapy toys or play therapy toys. These calm down tubes help with anxiety relief for kids and are easy to enjoy.

STRESS RELIEF TOYS FOR KIDS: Each calm down bottle offers a unique experience because each child reacts differently to a stressful situation. Kids or adults can enjoy an independent play or practice quiet focus.

ANGER MANAGEMENT TOYS: If kids are upset or stressed, encourage them to focus on the movement within the fidget tube. This allows them to slow down their heart rate and respiration as they turn their attention to there.

Table Of Contents For This Page

It is not easy to introduce all aspects of custom hourgalss, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Applications For Liquid Bubble Timer

Liquid Bubble Timer are used for timekeeping, in kitchens, restaurants, everywhere.

At the same time, the flow of liquid will make people quiet. It can be seen everywhere in sports venues and beauty salons.

The flowing liquid hourglass stimulates people’s senses, and it is a toy for children’s concentration and ADHD training.

General Hot Selling Products

Sensory Fidget Tubes

- Customized Liquid Color

- Customized Plastic Case Color

- Customized Packing

- Customized LOGO

Regular size:4.4*4.4*21CM

Regular design:see the picture

Regular Packing: Each opp bag with white box, 72 pcs/ctn.

Carton size:46.75*35.34*35.5 cm 18.18kg

Sensory Fidget Tubes, Calming Toys for Kids, Occupational Therapy Toys, Play Therapy, Stress Relief Toy, Comfort Items for Anxiety, Calm Down Corner Supplies (Set of 4)

Liquid Moving Sand Art Picture

- Customized Liquid Color

- Customized Plastic Case Color

- Customized Packing

- Customized LOGO

Regular size:8.0*14.0CM for bubbler timer, 14.2*1.25 for moving sand art picture. Regular sand colors: pink, blue, green, red.Regular Packing: Each opp bag with white boxCarton size:42.5*29.3*31.3cm 12.18kg

Acrylic Volcano Timer

- Customized Liquid Color

- Customized Plastic Case Color

- Customized Packing

- Customized LOGO

Regular size:6.2*6.0*9.2CM

Regular sand colors: black, red, green, pink.

Regular Packing: Each opp bag with white box, 72 pcs/ctn.

Carton size:46.75*35.34*35.5 cm 18.18kg

Liquid Motion Bubbler Pens

- Customized Liquid Color

- Customized Plastic Case Color

- Customized Packing

- Customized LOGO

Regular size:1.0*16.0CM

Regular liquid colors: green, purple, red, blue,

Regular Packing:Packing:1pc/opp,50pcs/inner box, 300 pcs/cartonPen refill color same as liquid color and can be replaced

Liquid Motion Bubbler Timer

- Customized Liquid Color

- Customized Sand Color

- Customized Plastic Shape

- Customized Material Color

- Customized Packing

- Customized LOGO

Regular size: 5.2*3.1*13.4CM, 5.5*3.3*14.5CM, 6.4*3.8*17CM,

Each product with 2 differnt liquid color.

Regular liquid colors: green&red, Blue&Pink, Green&blue.

Regular Packing:1 pc/white box, 12 pcs/inner box.

Liquid Pens with Mini Globe

- Customized Liquid Color

- Customized Plastic Case Color

- Customized Packing

- Customized LOGO

Regular size:2.3*5.1*14.3CM

Regular liquid colors: green, purple, red, blue,

Regular Packing:Packing:1pc/opp,50pcs/inner box, 300 pcs/cartonPen refill color same as liquid color and can be replaced

Acrylic GEL Timer

- Customized GEL color

- Customized Timer

- Customized Packing

- Customized LOGO

Regular size:5.3×5.3×12 CM, 5.8×5.8×15.3CM, 8*8*20CM,

Regular sand colors: red, green, blue, pink, purple.

Regular Packing:1 pc/white box, 12 pcs/inner box.

Liquid Motion Bubbler Keychains

- Customized Liquid color

- Customized Timer

- Customized Packing

- Customized LOGO

Regular size:3.5*2.8*8.0cm

Regular liquid colors: red, green, blue, pink, purple.

Regular 1pc/bag, 50pcs/inner, 300pcs/ctn

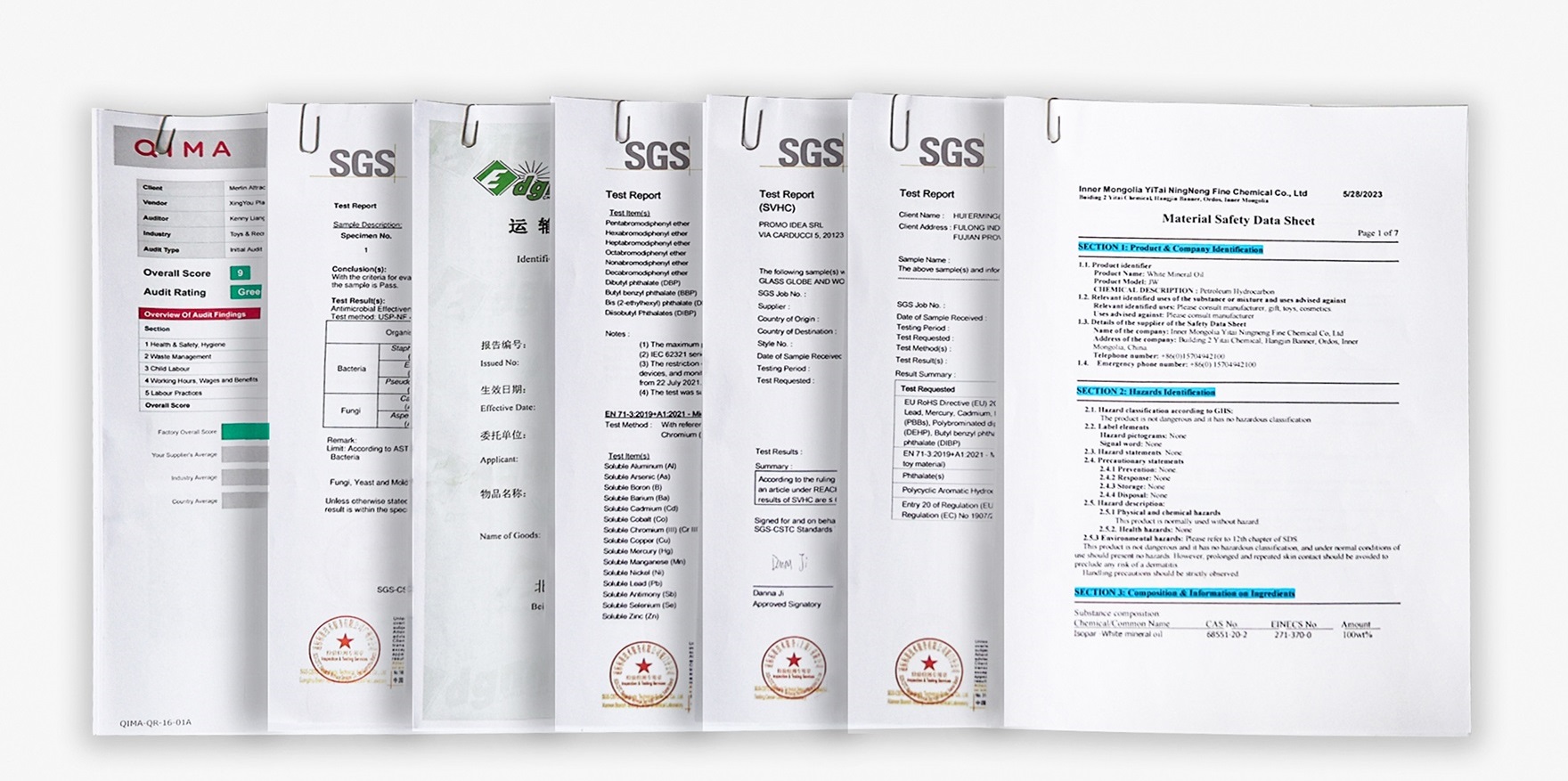

About Product Test

Product testing: discover defects and improve quality

Product testing is an important part of ensuring product quality. Through testing, we can discover problems in product functionality, performance, stability, etc., and make timely improvements. Here is some copywriting about product testing to help you better understand the importance of product testing.

Product testing, the guardian of quality

In the fierce market competition, product quality is the key to enterprise survival. Product testing is an important means to ensure quality. It can identify potential problems and improve product stability and reliability. We always adhere to strict product testing standards to protect the quality of your products.

Meticulous and meticulous, just for perfect quality

We know that product details determine quality. During the product testing process, we pay attention to every detail, from functions, performance to user experience, and comprehensively test various indicators of the product. Through meticulous testing, we create excellent product quality for you.

Product testing to witness strength

Our R&D team has rich experience and professional skills and conducts comprehensive testing on different products. Whether it is performance testing, compatibility testing or security testing, we can provide professional solutions. Our strength makes our products invincible in the market.

Product testing, continuous improvement

During the product testing process, we not only discovered problems, but also continued to collect user feedback and suggestions. These valuable opinions will help us continuously optimize our products and enhance user experience. Through continuous improvement, our products will become more complete and meet your needs.

Product testing, quality assurance

Quality is the lifeline of products. We go through strict product testing processes to ensure that every product delivered to you meets high quality standards. Our commitment is: to protect the quality of your products and make your choice worry-free.

When you choose Handvivo product , you will receive professional and comprehensive technical support. We will serve you wholeheartedly and jointly witness the excellent quality of our products

HANDVIVO MANUFACTURER

Handvivo located in Qingxi Town, Dongguan City, the manufacturing center of Guangdong Province.

Originating from Sunny Lee’s innovative spirit in 2013, in a dilapidated factory,

Handvivo has now developed into one of the large-scale customization manufacturers in Guangdong Province, China, with a factory of 6,000 square meters, 300 employees, a R&D team of 20, and a sales team of 20 It has more than 400 sets of self-owned molds and provides services to millions of customers around the world.

Its daily production capacity is 20,000 pieces of customized products, its annual export volume is 200 containers, and its products are shipped to more than 170 countries around the world.

Injection moulded acrylic accessories

Make Logo Printing

Put 3D Cartoons inside Acrylic Case

Make Customized 3D Cartoons

Liquid filled

QC department inspects products

Packing the products

Finished goods in the warehouse

Estimated Cost Analysis For Liquid Timer

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation.

Let's use a 5-minute glass hourglass as an example, 5 minute hourglass, Size: 9*5.5cm packing: Each foam with box, 120pcs per box, carton size: 60*60*40CM, weight: 9KG

$880

Take US as an example, total: 1.30CBM, 81KG by sea freight schedule: around 30 days after vessel leave

$480

The Process Flow & Duration Estimation

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation.

Step 1: Obtain designs and communicate details (3-5 days)

If you have a design, please provide it directly

If you have an idea, please let us know, you can use pictures, hand-drawing, text, etc., our design team will combine the products to give you several different design solutions for you to choose from.

Step 2: Sampling (7-14 days)

After the design is confirmed, samples will be produced according to the size, shape, color, and position of the manuscript.

Step 3: Pay The Bill (within 1 day)

All materials involved in the design draft are ready to be sent to the proofing workshop within 1 day.

Step 4: Bulk Manufacturing (30-45 days)

After the samples and orders are confirmed, a production notice will be sent to the workshop, and the workshop will start mass production and internal QC inspection according to the company’s production flow chart.

Step 5: Shipping

Our Port Name : Shenzhen

Air Express: 5-7days

Air Freight: 15days

Sea freight: 30-40 days different time in different countries

Want to know how to compress lead times?

a. Confirm samples through pictures and videos, saving sample delivery time

b. Directly confirm the order, we will make pre-production samples at the same time of ordering raw materials, pre-production samples can be confirmed by pictures and videos, and large quantities will be produced directly after confirmation.

c. Copy our ready-made design

The Common Pitfalls When Purchasing

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation.

- Product surface scratches

- can't flow

- Inaccurate time

- Incorrect color

- Unsafe packaging

Introduction to Acrylic Limer Raw Materail We Used:

Polymethyl methacrylate (polymethyl methacrylate, commonly known as PMMA), known as acrylic, plexiglass, English Acrylic, Taiwan, China is called pressure, and Hong Kong is mostly called agaric glue, with high clarity, money , It is convenient for machining and manufacturing, etc. It is a glass that is often used instead of raw materials.

advantage:The relative density is lower than that of laminated glass,

High impact toughness PMMA has a lower melting point

Taiwan Chimei has higher light transmittance Invisible light

UV:

Infrared sensor

Material physical properties:

Due to its large branched chain, the viscosity of polymethyl methacrylate is relatively high, so the processing speed is relatively slow when heat treatment is used. The plexiglass plate can not only be drilled with a CNC lathe, but also can be drilled with a planer, and can be used toluene , chloroform, etc., can be bonded into various shapes, and can also be processed into various handicrafts such as large canopy canopies, small dentures and dental trays by injection molding, injection, extrusion and other plastic forming methods. Cyanoacrylates, dichloromethane, or chloroform, etc. can slightly melt the plexiglass plates, and then firmly bond the two plexiglass plates together. To produce 1KG of PMMA, about 2KG of crude oil is required. Under the condition of aerobic exercise, PMMA begins to ignite at 458 ℃, and after igniting, it turns into carbon dioxide, water, carbon monoxide and some low-molecular substances including formaldehyde.

Feedback From Customers, Why Choose Handvivo?

Customer purchases goods from our factory in. Amazon made intermediate profits from sales, This video from his introduction

The benefits of purchasing from the source factory:

a. OEM/ODM are welcome

b. More advantageous prices than wholesalers and intermediaries

c. Solve your problems directly and quickly, whether it is before production or after sales

d. You can get a bigger profit margin, whether it is selling on the online platform or in the physical store

e. Ten years of export experience to help you solve troublesome problems such as customs, transportation, and safe packaging.

FAQs

From Handvivo

Are you a factory or trading company?

We are a highly successful and rapidly growing family business that has expertly integrated manufacturing and trading of industrial liquid crafts gifts.

How to protect our rights?

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

What is the minimum order(MOQ)?

The minimum order quantity for customized products is 1000 pcs

The minimum order quantity for existing regular products is 500pcs

Can you provide a price list or quote for your products?

Yes, we can provide a price list for us existing design or a customized quote based on your specific product requirements, quantity, and other factors. Please contact our sales team for further assistance.

How long is the order production lead time?

1. Standard Products

- Lead Time: 1-2 weeks

- For items that are already in production or require minimal customization, lead times are generally shorter.

2. Custom Products

- Lead Time: 3-6 weeks

- Custom products may take longer due to design, material sourcing, and production adjustments. This includes items that need to be made to specific specifications or require special finishes.

3. Large Quantity Orders

- Lead Time: 4-8 weeks

- Bulk orders or high-volume production runs can take more time, depending on the capacity of the production line and the availability of raw materials.

4. Complex or High-Tech Products

- Lead Time: 6-12 weeks

- Products that involve complex manufacturing processes, advanced technology, or multi-part assembly may require longer lead times.

5. Rush Orders

- Lead Time: 1-2 weeks (with additional fees)

- Some manufacturers offer expedited production for an additional fee. However, this depends on the current production capacity and the nature of the order.

What are the common payment terms when purchasing from China?

Pay 30% in advance and 70% before shipment by T.T. (Standard Products)

Pay 100% in advance by T.T. (Existing Products)

Get started today!

OEM & ODM are both ok,

Find the one that works best for you.

If you need help, we’re here to assist.

Let us know how we can help you, and we’ll be in touch with the information you need to select the best choice.

Contact us today and we will help you winner the order.

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ask For Quote Now!

REPLY WITHIN 24 HOURS

OEM & ODM are welcome.

Find the one that works best for you.