Carefully clean and inspect the mold to ensure that there are no impurities or damages on its surface. Then, carefully install the mold into the injection molding machine. Through the precise operation of the injection molding machine, an acrylic shell is produced. The back panel is injection molded using a separate mold, and the main body of the photo frame consists of two different components. The injection molding process of these two components also requires strict control of parameters to ensure the precise matching of dimensions.

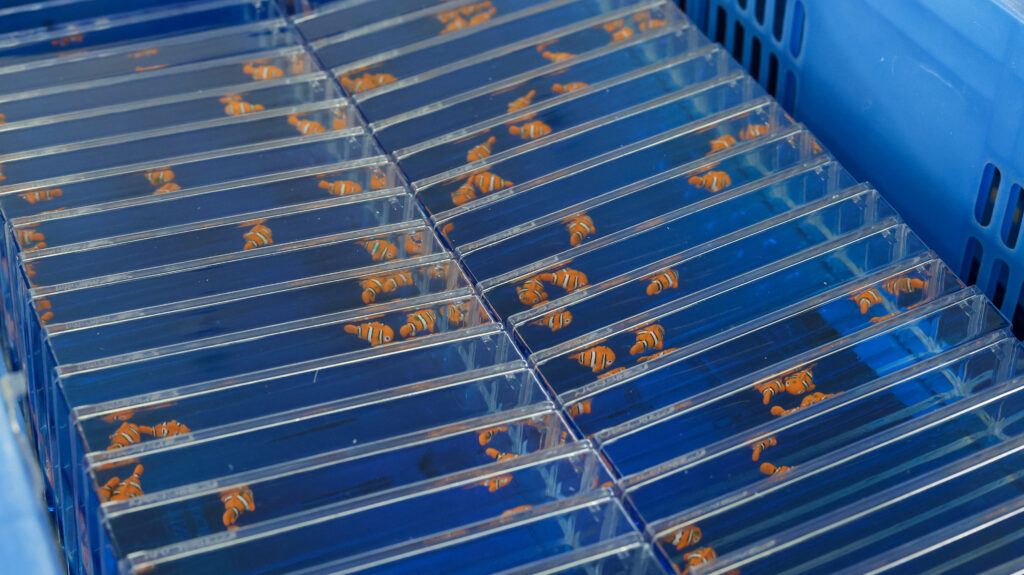

Then, put the carefully selected glitter powder or lovely cartoon decorations into the shell. After that, use the ultrasonic welding process to weld the two components of the photo frame main body together. During the ultrasonic welding process, the two components are closely fused into a solid whole through high temperature and vibration. When welding, pay attention to controlling the welding time and intensity to avoid situations such as weak welding or damage to the components.

Subsequently, use a vacuum machine to fill most of the liquid into the photo frame through specific holes. Since there may be some areas where the liquid cannot be completely filled, for the parts where the liquid is not fully filled, manual and meticulous refilling of the liquid is required to ensure that the liquid inside the photo frame is filled evenly and reaches the specified amount.

After the filling is completed, thoroughly clean the surface of the product to remove the remaining liquid, impurities, stains, etc. on the surface. After cleaning, place the product in a clean and ventilated place to dry, ensuring that the surface of the product is completely dry.

Then, conduct a sealing inspection of the product to check whether the product leaks liquid. The specific inspection method is to use an air gun to blow along the ultrasonic welding line for a full circle and observe the liquid situation inside the photo frame. If the liquid inside does not move when blowing air, it means that the sealing is good; if the liquid has undulations, it indicates that the sealing is insufficient, and this product is a defective product, which requires reprocessing or scrapping.

After passing the sealing inspection, polish the surface of the product to make the surface smoother and more glossy. After polishing, perform the film application operation to further protect the surface of the product. Finally, dry the surface of the product to ensure that there are no water stains, dust and other impurities on the surface.

Finally, the QC personnel conduct a strict inspection of the product’s appearance, LOGO and other quality issues. Only after all quality inspection items are qualified can the product packaging work begin. When shipping, in order to ensure the safe transportation of the product, use a pallet for packaging.

Hot sale design