Glitter Photo Frame Manufacturer

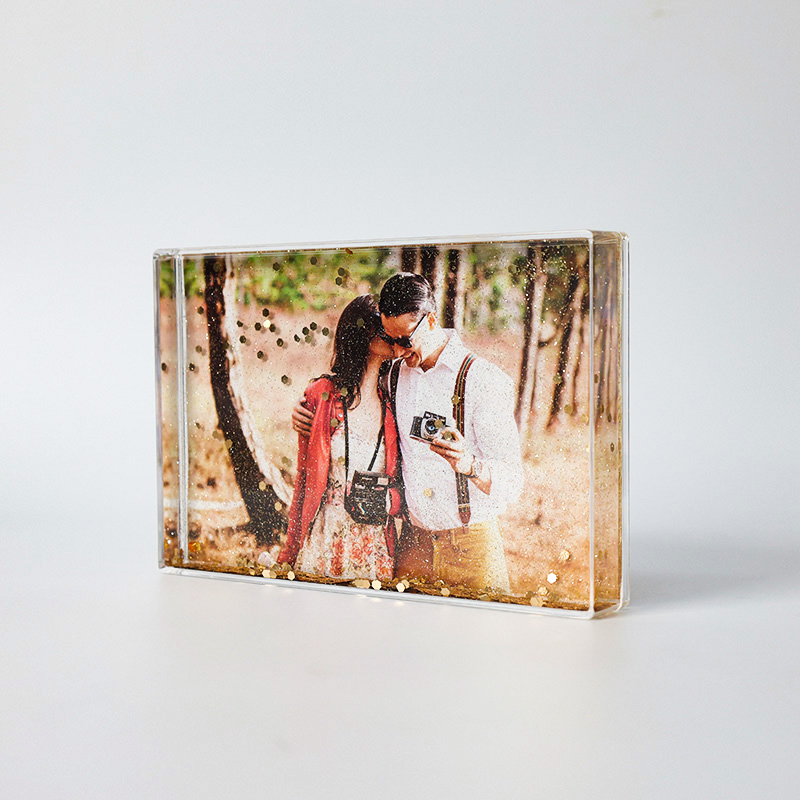

Filled with water and glitter

Various shapes and sizes

Customized 3D floater

Best selling size is Insax 2×3 inch, 4×6 inch

Customized inner photo and glitter

Low MOQ only 500 pcs

B2B Expert

No Middle Man

In recent years, the liquid glitter photo frame in the market share more and more, but also more and more accepted and recognized by the public, the beginning of people will worry about the liquid ooze out, worried about the safety of transportation, liquid environmental testing issues and so on. From not being recognized by the public to the development of today’s stores everywhere in all kinds of stores.

I entered the industry from 2012 has been twelve years, witnessed the liquid product one after another technical innovation, quality improvement, design innovation of the whole process, now, liquid photo crafts has been a mature and perfect change of high-grade decorations. It is rich in products, multi-functional, novel and creative styles, good at customization, has been from the beginning can only be integrated into the cheap promotional gifts market to the present day, major supermarkets, retail stores, brand companies scramble to order.

I am honored to witness the growth of the liquid photo frame of the whole process, now, I want to tell you:

Liquid photo frame snow globe product quality is superior, exquisite design, environmentally friendly materials, safe packaging, transportation, testing and worry-free. It is a holiday gift, brand promotion, travel souvenirs market is very best-selling products.

In this article I will discuss the following topics with you from a perspective of someone who has been there:

1:What is the difference in raw materials of the liquid frame?

2:What are the liquid ingredients?

3:What are the innovative designs?

4:What sizes of liquid glitter photo frames are available? What are the functions?

5:What are the brands we have cooperated with?

6:Production process introduction

7:Is the transportation safe?

8:What are the quality requirements for liquid gifts in importing countries?

What is the difference in raw materials of the liquid frame?

It is different. In order to show the liquid and design inside the product, we require the raw material to be highly transparent, like crystal, but not as fragile as glass. Also in order to ensure that the appearance is not scratched, not easy to break, the material must be very tough, flexible. Can withstand high temperature, can be frozen. Durable not easy to break, and no matter how long it does not fade yellow, there are many different materials on the market, each material there are many different brands, such as ABS, PS, PC, PMMA (ACRYLIC )and so on.

I will analyze the advantages and disadvantages of each material one by one.

ABS

ABS is synthesized from three chemical monomers: acrylonitrile, butadiene and styrene. (Each monomer has different properties: acrylonitrile has high strength, thermal and chemical stability; butadiene has toughness and impact resistance; and styrene has easy processing, high gloss and high strength. The polymerization of the three monomers produces a terpolymer with two phases, a continuous phase of styrene-acrylonitrile and a dispersed phase of polybutadiene rubber).

Morphologically, ABS is an amorphous material with high mechanical strength and a good combination of “firm, tough and steel” properties. It is an amorphous polymer, ABS is a general-purpose engineering plastics, its varieties, a wide range of uses, also known as “general-purpose plastics”, (MBS known as transparent ABS), ABS is easy to absorb moisture, specific gravity of 1.05g/cm3 (slightly heavier than water), low shrinkage (0.60%), dimensional stability, easy to molding process.

The characteristics of ABS depend mainly on the ratio of the three monomers and the molecular structure of the two phases. This allows for a great deal of flexibility in product design and has resulted in hundreds of different qualities of ABS materials on the market. These different qualities offer properties ranging from medium to high impact resistance, from low to high gloss and high-temperature twisting properties, etc. ABS materials offer superior processability, appearance, low creep and excellent dimensional stability, as well as high impact strength.

ABS is light yellow granular or bead opaque resin, non-toxic, odorless, low water absorption, with good overall physical and mechanical properties, such as excellent electrical properties, abrasion resistance, dimensional stability, chemical resistance and surface gloss, and easy to process molding. Disadvantages are weather resistance, poor heat resistance, and flammable.

PMMA(Acrylic)

1 .PMMA properties

PMMA is an amorphous polymer, commonly known as Plexiglas. Excellent transparency, heat resistance (heat distortion temperature of 98 ℃), with good impact resistance characteristics, the mechanical strength of its products, low surface hardness, easy to be scratched by hard objects and leave traces, compared with PS, not easy to be brittle, specific gravity of 1.18g/cm3.

PMMA has excellent optical properties and weather resistance. White light penetration of up to 92%. PMMA products have a very low birefringence, especially suitable for the production of video discs, etc. PMMA has room temperature creep characteristics. As the load increases, time growth, can lead to stress cracking phenomenon.

2. PMMA process characteristics

PMMA processing requirements are more stringent, it is very sensitive to moisture and temperature, fully dry before processing (recommended drying conditions of 90 ℃, 2 ~ 4 hours), its melt viscosity is larger, need to be higher (225-245 ℃) and pressure molding, mold temperature at 65-80 ℃ is better.

3.Typical application scope.

Plastic industry, automotive industry, pharmaceutical industry, industrial applications, consumer goods, etc. Handvivo’s products are mainly made of acrylic.

Acrylic is a very good kind of plastic, he is recognized as the queen of plastics, easy to process, more colors, more thickness.

Acrylic sheet transmittance of up to 92% or more, known as crystal glass, ordinary glass transmittance of about 85%. Under the sunlight, acrylic sheet is crystal clear and beautiful!

PS

Polystyrene (Polystyrene, abbreviated PS) has very high transparency, light transmission rate of up to 90% or more, good electrical insulation properties, easy coloring, good processing fluidity, good rigidity and good chemical resistance. The shortcomings of ordinary polystyrene are brittle, low impact strength, prone to stress cracking, poor heat resistance and intolerance of boiling water. The birefringence is large, its optical properties are worse than PMMA, but the moisture absorption rate is low, only 0.02%. It can be freely colored, odorless, tasteless and non-toxic.PS’s thermal conductivity does not change with the temperature, and it can be used as a good freezing insulation material. Processed into optical products need to pay attention to the birefringence of PS products, easy to stress white and cracking, products with poor impact resistance, low-temperature brittleness, and weather resistance of PS products.

Moreover, the weather resistance of PS products is poor, and they will turn yellow and cloudy when stored for a long time and irradiated by sunlight.

PC

PC is an amorphous, odorless, non-toxic, highly transparent colorless or slightly yellow thermoplastic engineering plastics, with excellent physical and mechanical properties, in particular, excellent impact resistance, tensile strength, bending strength, compression strength; good toughness, good heat and weathering resistance, easy coloring, low water absorption.

PC heat distortion temperature of 135-143 ℃, creep is small, dimensional stability; good heat resistance and low temperature resistance, in a wide range of temperatures with stable mechanical properties, dimensional stability, electrical properties and flame retardant, can be used for a long time at -60 ~ 120 ℃; no significant melting point, at 220-230 ℃ is molten; due to the rigidity of the molecular chain, the viscosity of the resin melt is large; Small water absorption, small shrinkage (generally 0.1%~0.2%), high dimensional accuracy, good dimensional stability, small film permeability; self-extinguishing material; light-stable, but not UV-resistant, good weather resistance;

Oil-resistant, acid-resistant, not resistant to strong alkali, oxidizing acids and amines, ketones, soluble in chlorinated hydrocarbons and aromatic solvents, inhibit bacterial properties, flame retardant properties and anti-pollution, long-term hydrolysis and easy to cause cracking in the water, the disadvantage is that due to poor fatigue strength, prone to stress cracking, solvent-resistant, poor mobility, poor abrasion resistance. pc can be injected, extruded, molded, blow molding thermoforming, printing, bonding, coating and Machining, the most important processing method is injection molding.

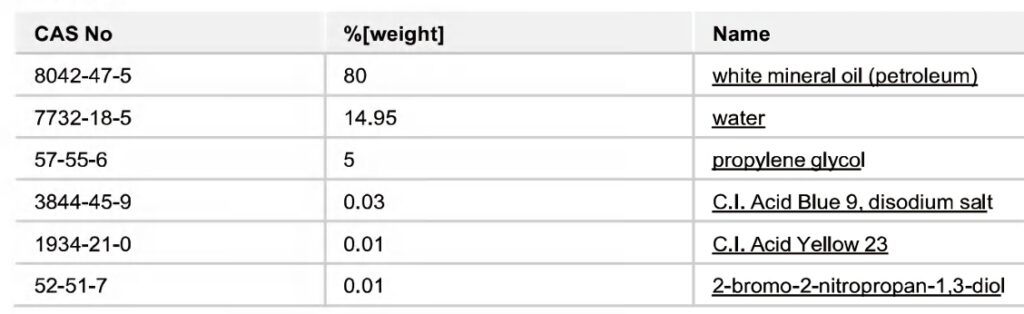

What are the liquid ingredients inside the glitter photo frame?

There are two types of liquid components, differentiated by design.

The first one is oil + pure water.

The second one is 100% pure water.

First introduce the first, oil + pure water, oil is a food-grade white mineral oil. The ignition point is very low, transparent, not yellow, moderate consistency, is put into the acrylic crafts in a more suitable choice, the specific composition table is as follows.

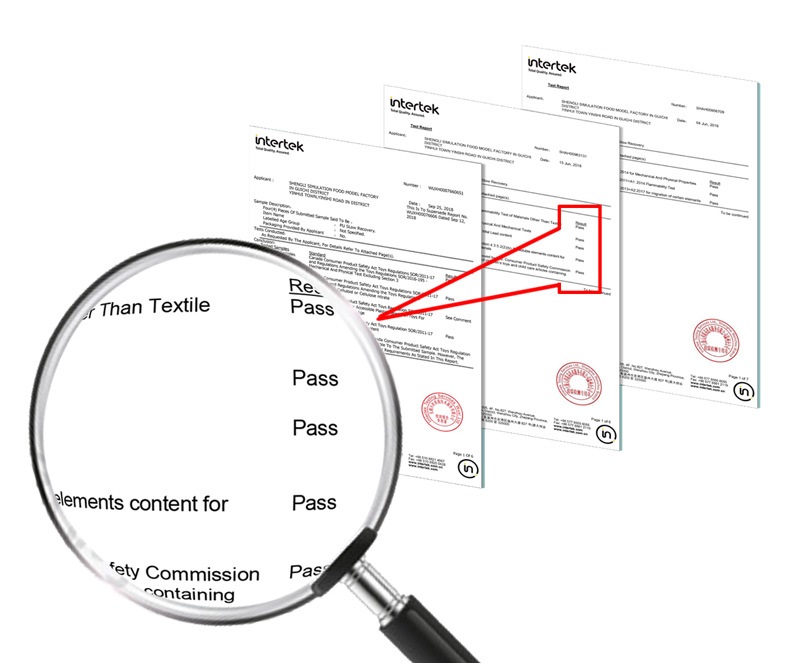

The most common tests for exporting to EU&US market: EU RoHS Directive 2011/65/EU Appendix II Amendment Directive (EU) 2015/863 – Lead, Mercury, Cadmium, Chromium Hexavalent, Polybrominated Biphenyls (PBBs), Polybrominated Diphenyl Ethers (PBDEs), Dibutyl Phthalate (DBP), Benzyl Bis(2-ethylhexyl) Phthalate (BBP), Dibutyl 2-Ethyl Phthalate (DEHP) and Diisobutyl Phthalate (DIBP), all of which are 100% passed by us. (DBP), butyl benzyl phthalate (BBP), di(2-ethylhexyl) phthalate (DEHP), and diisobutyl phthalate (DIBP), and we have a 100% approval rate for these ingredients.

Other tests we have passed for the liquid portion: PAHs, REACH, RoHS, FDA, ASTM F963 ,CP65

Oil + pure water design is the main part of the water can be customized to add color powder after adjusted to different colors, the color is based on the international Pantone card number to debug, close to the degree of 95% or so.

Usually we will first fill the oil into the acrylic products, and then add colored water, fill the product will be presented after part of the transparent color, part of the color, the transparent part is oil. The colored part is water, because the density of oil is lighter than water, oil is always on top of the water. Colored water is always in the oil below, when you shake the product will show the same feeling of waves or surfing, but the oil and water will never be fused together, each good. (Here to put the oil + water pictures)

Just because there is a demarcation line between oil and water, our lovely designers and put some 2D PVC pieces, 3D cartoons, colorful glitter accessories in the product when the surface, they have been floating in the oil and water, not floating, not sinking. Very creative, very vivid. (The latter will speak separately when the design will explain this part in detail …)

Next, we will introduce the second ingredient: 100% pure water.

Ingredients: Water 94.99%, Proplyene Glycol 5%, Bronopol 0.01

If you are worried about the composition of the oil or the safety of the transportation process, then the pure water frame products is your best choice, he added a small amount of Proplyene Glycol and Bronopol, in addition to 100% pure water, very safe and environmentally friendly. And it is very popular in the market.

Water we will add color powder to adjust the color, the color can be adjusted according to the international Pantone color card number, color proximity of about 95% or more, we fill the oil and water into the product can present a two-tone effect, part of the transparent color part of the color, it is clear that the transparent part is the oil, the color part of the water, you can try to shake the product, it will show the feeling of the surf, the harder the more turbulent. When the frame is placed on the desktop after the static it will sink down to show the effect of crystal clear. Our most commonly used colors are blue liquid for ocean beach aquarium market, green liquid for nature green environmental protection style, yellow liquid for autumn, orange liquid for Halloween, pink liquid for romantic Valentine’s Day, and red liquid for Christmas Day style and so on, if you have special requirements, we can always customize for you.

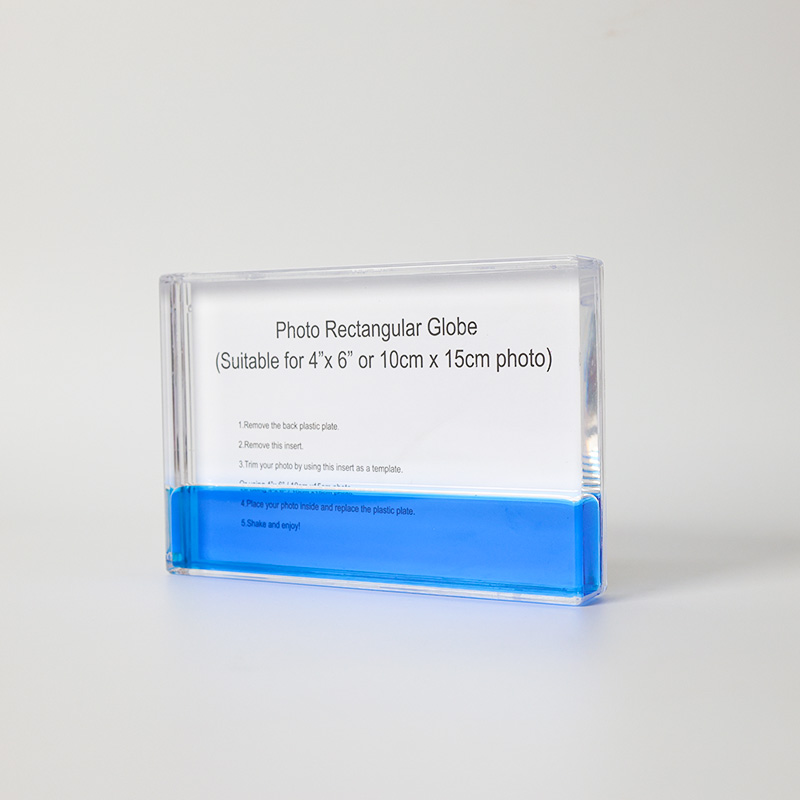

Show snow globe photo frame product images of oil + water

oil & blue water photo frame

oil & blue water and glitter photo frame

Oil & Purple Liquid photo frame

Oil & Green Liquid photo frame

oil and blue liquid with 3D fish Aquarium Photo Frame

customized liquid photo frame

What are the innovative designs of liquid glitter photo snow globes?

Acrylic glitter photo frame snow globe design is divided into: oil + water design and purified water water design.

The first type, oil + water design.

The oil is transparent and colorless slightly viscous, filled with acrylic transparent shell inside will make the product look more translucent.

Water is 100% pure water, without any added ingredients.

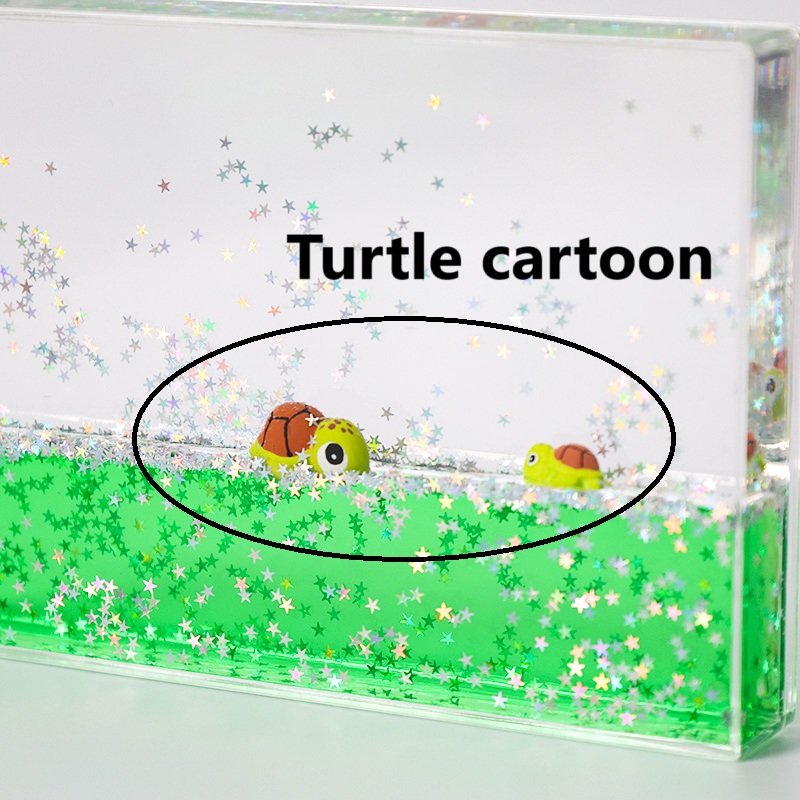

Because there will be boundaries between oil and water, lovely designers will also put some 3D cartoons, glitter, or PVC pieces, etc. in it, these accessories will always float in the oil and water, will not sink or float up, when you shake the product, they will be free to swim around in it, very vivid and energetic, put you and your family’s photos, the photos will be alive.

Sea lions, octopuses, flying fish, whales, dolphins, shells, starfish, etc. Animals: hedgehogs, tigers, rabbits, frogs, birds, cats, dogs, snakes, cows, goats, etc. Christmas cartoons include Santa Claus, snowmen, Christmas trees, Christmas hats, Christmas stockings and so on

Of course, we are also very good at customizing your own design, the material of 3D cartoon is resin, resin is a natural environmentally friendly material and the most suitable for molding shapes and sizes, as long as you provide us with pictures, we can design it. And the mold cost is very cheap, about USD150 or so, the mold time is about one week (send customer design, mold drawing, finished sample, three kinds of pictures, so that customers can see the effect of opening the mold at a glance) 3D Cartoon Liquid Photo Frame Pictures

Second, 100% pure water design

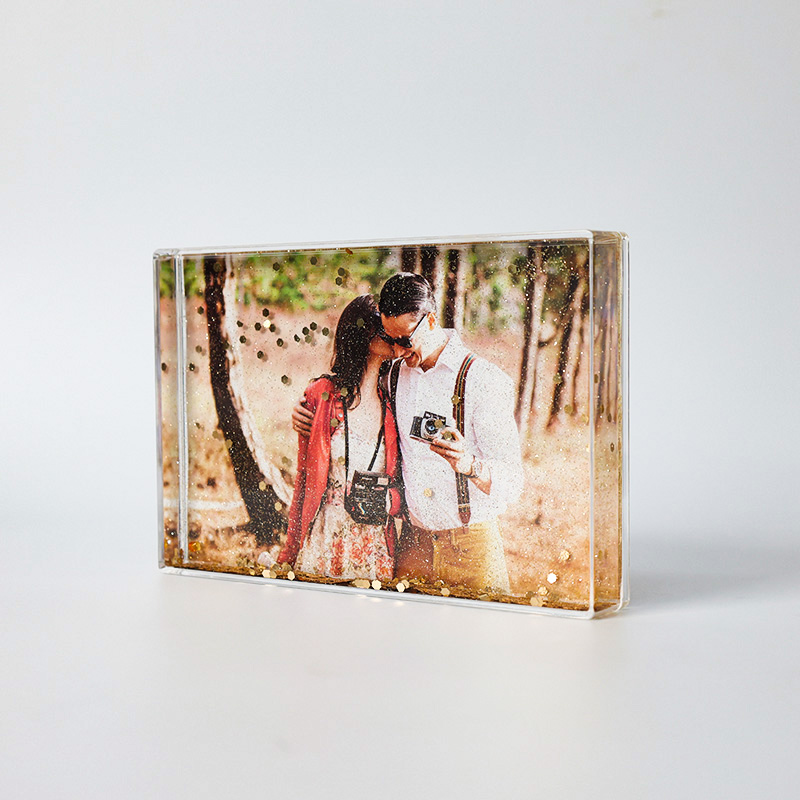

Glitter photo block design is the best seller in the market, especially 4×6 inch glitter photo frame, which is the most popular among consumers. Usually, small snowflake particles are added to the product to present the feeling of snowflakes dancing, which is especially suitable for Christmas gift sales. Colorful glitter, fine powder, sequins and so on. These accessories are PET environmentally friendly materials, very thin and light, placed in the product, as long as the gentle shake will be free to float and rotate up. When the lovely accessories are still for a period of time, it will become a clear and clean photo frame.

Our PET glitter will not fade, change color or yellow when put in liquid. And there are hundreds of different shapes for customers to choose for free. Regular shapes of sequins are quadrangle, hexagon, prism, strip, V-shape, tube, irregular pieces and so on. Special shapes sequins are pentagram, heart, moon, circle, plum blossom, butterfly, triangle, diamond, cherry blossom, dolphin, dinosaur, musical note, maple leaf, cloud, snowflake, high heel, four-pointed star, rice star, smiley face, bat, unicorn, Christmas tree, Christmas hat, skull, letters, etc. 3D sequins have three-dimensional diamonds, three-dimensional triangles, three-dimensional arrowheads, three-dimensional rectangles, three-dimensional square, three-dimensional prisms, three-dimensional pentagrams, etc.

The best-selling design of 4x6 acrylic photo frame snow globe on the market

Snow glitter photo frame, especially suitable for winter, or Christmas season, when you shake the product will show the scene of snowflakes, is the best gift for family and friends at Christmas, especially loved by children.

Red heart glitter photo frame, red heart glitter special romantic, especially suitable for Valentine’s Day, weddings, marriage proposals and other special moments, treasure the happiest moments of you and your lover.

Gold glitter photo frames is perfect for celebration, friends gathering or graduation party favors, gold glitter will make you and your friend’s life sparkling and glittering.

Silver glitter photo frames design is a cozy, cool, sexy and fashionable product, popular with many business people, fashion crowd, coffee shop decoration market.

Black glitter picture frames is best gift for the Halloween gifts, especially bat glitter photo frames and pumpkin glitter photo frames, are the most special gifts for Halloween.

Best size is 4×6 photo frames bulk.

snow glitter photo frame

red heart glitter photo frame

Valentine’s Day Photo Frame Gift

gold glitter snow globe photo frame

silver glitter picture in photo frame

christmas glitter photo frame

blue glitter picture in photo frame

What sizes of liquid glitter picture frames available?

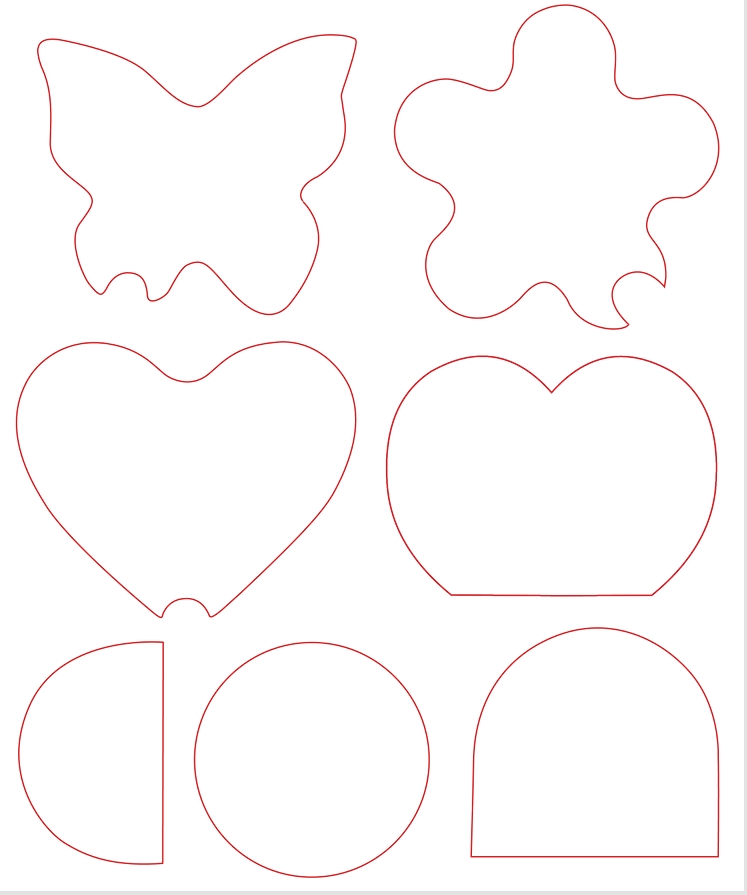

Regular product sizes are: 2.1*3.4 inch, 4*4 inch, 4*6 inch, 5*7 inch, which can be put into the international common photo.

Irregular shapes are: round, semi-circle, heart, diamond, oval, pentagram, apple, egg, snowflake and so on. Egg shape, snowflake shape and so on.

P.S Their raw materials, liquid ingredients, production process are all the same.

2.1*3.4 inch, 4*4 inch, 4*6 inch, 5*7 inch frames fit international photo sizes.

Regular product sizes are: 2.1*3.4 inch, 4*4 inch, 4*6 inch, 5*7 inch acrylic photo frame which can be put into the international common photo.

Different photo sizes of snow globe photo frame die cuts

Irregular shapes are: round, semi-circle, heart, diamond, oval, pentagram, apple, egg, snowflake Egg shape, snowflake shape snow globe picture frame.

Handvivo as the source manufacturer, you see in the various e-commerce platforms, C-end retail stores, travel souvenir stores, retail stores, etc. This product source manufacturer is from handvivo. We developed our own liquid photo frame series products 8 years ago, and it has been a bestseller since then, we have produced countless different designs, and we have served hundreds of different customers in 37 countries all over the world and we have never received any complaints about the quality of the frames. We have served hundreds of customers in 37 countries all over the world, and we have never received any complaint because of the quality problem.

Because of our excellent quality, strict management, good reputation, make our customers in the market share are getting bigger and bigger, we are honored to accompany them to grow into the largest wholesaler in the market.

What are the features of the Liquid Glitter Picture Frames Snow Globe?

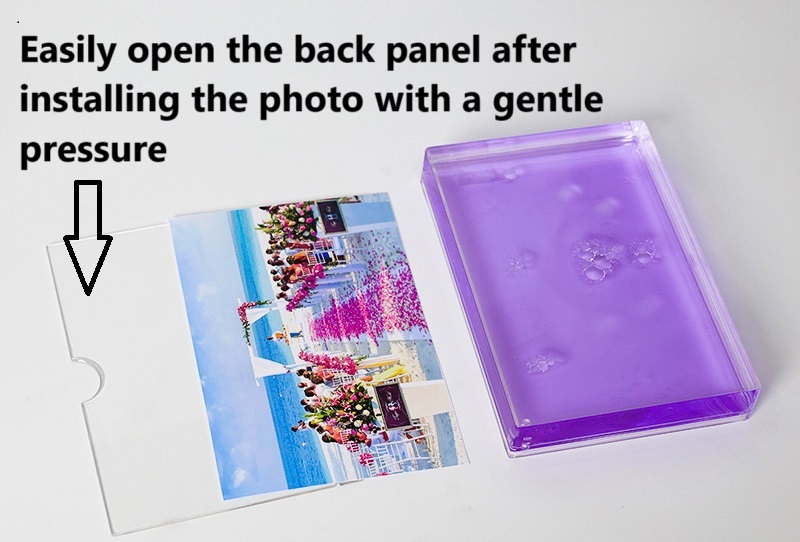

The function of photo in snow globe photo frame is surely for mounting photos, there is a separate backside, easy to open and directly embedded in the photo, and then gently press the backing plate to tighten it, and then repeat this action if you want to replace other photos.

In addition, because of the unique design of liquid glitter makes it more than the traditional photo frames a lot of its display functions, such as home decoration, brand display, Pin Auction enhancement, brand publicity, brand promotion and so on, choosing it for promotion will surely bring your ideas to the next level.

What brands have you worked with of the glitter photo block?

Brands we have worked with include: 3M, Sony, Dove, Nestle, Starbucks, DHL, Amani, TOD, McQueen, Lamy, Montblanc, Samsung, Sanrio, Disney and more.

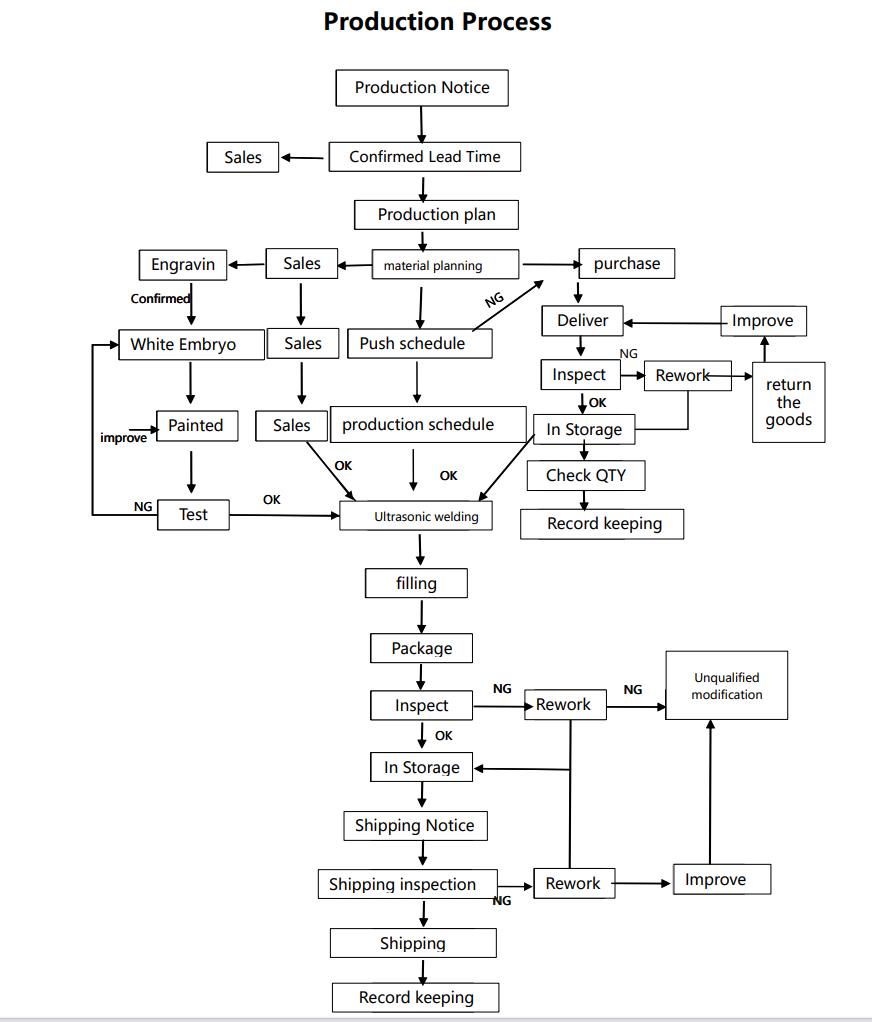

Introduction to the glitter picture frames production process

Brands we have worked with include: 3M, Sony, Dove, Nestle, Starbucks, DHL, Amani, TOD, McQueen, Lamy, Montblanc, Samsung, Sanrio, Disney and more.

After each order is confirmed, it enters the production department, and there are many production processes from the beginning to the shipment. There are many small divisions of labor between each process.

Handvivo has been in this field for 10 years, specializing in the production of liquid glitter quicksand crafts, gifts and promotional items, especially glitter photo frames, glitter quicksand keychains, photo snow globes, quicksand toys, office stationery gifts and so on, which are very popular in Europe and the United States market.

We have a strict management system to ensure that every order can be quality assured and shipped on time.

We have a professional sales team to provide 24 hours service for our customers.

We have a professional logistics team to deliver each order safely to customers.

We have a professional after-sales team to ensure that your purchase is worry-free.

Below we explain the most important production processes:

Step 1 : confirm the production order

When the sales received customer orders, according to the order requirements to the production department under the production order, the production department according to the order requirements, production capacity, the development of the production plan, confirm the production delivery date.

Step 2: Material Purchasing

Purchasing Department according to the order requirements for the purchase of raw materials, accessories, packaging materials, etc., the warehouse will be for the material inspection, counting the number of materials to ensure that the first step of the material without any quality problems, after confirming that there is no error into the auxiliary materials warehouse.

On the acrylic photo frame the most important part of the raw materials, we use Taiwan Chimei acrylic materials, compared to other brands of materials, this brand is expensive but has a better transparency, chemical stability and weather resistance, easy to dye, easy to process, beautiful appearance, and in terms of environmental protection has a special design, such as recycling is better, the production process of the environmental impact of the smaller.

Step 3: Order mass production

1: Injection molded acrylic photo frame shell

Injection molding is the use of thermoplastic or thermosetting plastic molds to make various shapes of plastic products, our factory has 10 sets of injection molding machine 24-hour shift production of plastic shells, a day capacity of about 40,000 products

2:Printing Screen Logo Printing

For customized printing, you need to arrange the printing screen, and then the logo will be printed on the acrylic photo frame.

3: Customized 3D cartoons

If there is a custom 3D cartoon request order, at the same time to arrange custom cartoon mold engraving, white embryo production, painting colors, buoyancy test, etc., to be confirmed by the customer, 3D cartoon can be produced in large quantities, the cartoon will be put into the plastic shell inside the production, if the customer needs to be filled with glitter inside the shell, and at the same time, also put into the glitter.

Our glitter is available in a wide variety of shapes and colors, and will sparkle when placed inside liquids, which is highly appreciated by consumers.

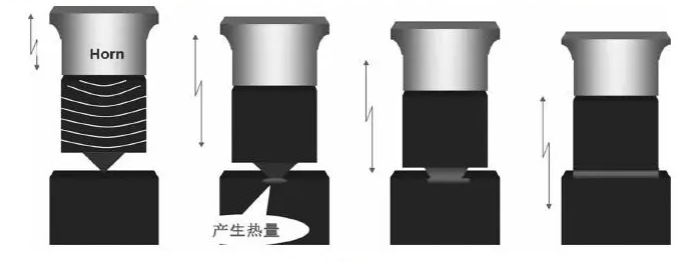

4:Ultrasonic & Welding

Ultrasonic welding machine refers to the welding head will receive the vibration energy transferred to the interface of the plastic parts to be welded, in the region, the vibration energy through friction is converted to heat, the plastic will melt, vibration stops to maintain a short period of time on the plastic parts of the pressure so that the two plastic parts in a molecular connection to solidify as a whole, so that the product is dissolved in the same way and well sealed.

5: Liquid filled in products

We pass the vacuum machine to fill the liquid into the ultrasonic welding good plastic products, and then use the syringe to manually replenish the products that are not filled with liquid, make sure that each one is 100% filled and then use the transparent TPR material to plug the injection hole tightly to make sure that the liquid won’t flow out, and won’t enter the air.

6:QA Inspection

For each product, the QA department will test the sealing and ignition point, evaluate the appearance, review the AQL quality standard and then notify the packing house to pack the product. If it is not qualified, we will ask for improvement and check again to make sure it meets the AQL quality requirements before arranging the packaging workshop to pack the big goods.

Step 4: Finished product packaging

Each order is customized with packaging materials according to customer requirements, and we pack large shipments according to customer requirements.

Ensure that the number of incoming boxes is correct, the marking is correct, and the design is matched correctly.

Finished goods in storage

Warehouse according orders quantity, check with quantity of production are matched there is a shortage of the number of 2 days to make up for all the full

shipping notice

Warehouse sends completed orders, large production pictures, and packing lists to sales. The salesperson informs the customer to prepare the warehouse for shipment and collects the balance of the order.

Step 5: Shipment

Upon receipt of the customer’s consent to ship the order and the balance of the order, our professional logistics team is responsible for arranging the shipment of the order.

For bulk cargo, we usually use pallets for shipment.

For container cargo, our regular outer box, middle box, can meet to ensure the safety of the transportation process.

For sea cargo, the logistics department will book the cabin with the freight forwarder, get the warehouse receipt and send the goods into the designated warehouse and complete the local customs procedures to ensure that the goods are released on time to load the container on the ship.

For air cargo, we will use safer packaging to ensure the safety of the goods during transportation, and will follow up the progress of transportation and customs clearance to update the progress to customers.

For orders with testing requirements, we will arrange testing in advance to ensure that the testing is completed before shipment.

Finally, our logistics team will send the required customs clearance documents, invoices, packing lists, certificates of origin, bills of lading, etc., to our customers by mail or courier to assist them in completing local customs clearance.

full container shipment

Are liquid products safe during transportation?

Because liquid products are fragile products, we have considered this factor in the choice of packaging materials and packaging design, we use the middle box, the outer box, are five layers of hardened and thickened AB environmentally friendly paper, in line with the quality requirements for export, but also in line with the conditions of environmental protection and recycling of paper products, the weight of each box of products is basically controlled in the 12KG or less, you do not have to worry about, the transportation process is very safe.

If it is a bulk cargo by sea, we will give the goods on a plastic pallet, boxes are fixed in the plastic pallet, each transit, moving process, the outer box does not have to move alone, are moving the pallet with a forklift can be, so as to ensure that each box of goods are very safe.

If it is a sea container cargo, we will call the pallet truck to the container to our factory direct loading, our professional loading masters, will be a row by row of each outer box to set a good position, a regular box by box stacked up to ensure that each layer of safety. And as soon as possible to maximize the possibility of loading more goods, try to help customers to save costs, the more loaded down the equalization of the shipping cost is lower, is not it?

If it is air cargo, we will be more careful and prudent in the packaging design, usually consider the inside of the outer box, front, back, left, right, up and down with a layer of 2CM thickness of pearl cotton to protect the products inside. So that even if the air transportation of a box of moving boxes are not worried about the products are crashed.

Sometimes, liquid products need to do a transportation safety appraisal report in advance, the cost of this test is about USD60 a product, the time is about 2 days to complete.

What are the import customs requirements for liquid crafts?

Customs requirements for imported liquid crafts vary from country to country, depending on factors such as the nature of the liquid, its composition and destination.

Typically, clear identification of the product’s liquid type, use, and composition is required, and most customs authorities require a detailed list of the product and its composition.

Prepare a commercial invoice including product description, value and quantity, packing list, place of origin, specific certifications.

Customs duties are applied at the time of importation, the amount of which depends on the HS code of the product (HS code of our products is 39264000) and the value, quantity and volume of the goods.

Packaging and transportation must be in accordance with air or sea freight regulations, and provide MSDS content report if necessary.

For detailed transportation requirements, please contact your courier or freight forwarder for packaging and transportation instructions, or contact us and tell us the destination country, our professional logistics team will assist you to receive the goods safely and smoothly!

FAQs

From Handvivo

Are you a factory or trading company?

We are a highly successful and rapidly growing family business that has expertly integrated manufacturing and trading of industrial liquid crafts gifts.

How to protect our rights?

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

What is the minimum order(MOQ)?

The minimum order quantity for customized products is 1000 pcs

The minimum order quantity for existing regular products is 500pcs

Can you provide a price list or quote for your products?

Yes, we can provide a price list for us existing design or a customized quote based on your specific product requirements, quantity, and other factors. Please contact our sales team for further assistance.

How long is the order production lead time?

1. Standard Products

- Lead Time: 1-2 weeks

- For items that are already in production or require minimal customization, lead times are generally shorter.

2. Custom Products

- Lead Time: 3-6 weeks

- Custom products may take longer due to design, material sourcing, and production adjustments. This includes items that need to be made to specific specifications or require special finishes.

3. Large Quantity Orders

- Lead Time: 4-8 weeks

- Bulk orders or high-volume production runs can take more time, depending on the capacity of the production line and the availability of raw materials.

4. Complex or High-Tech Products

- Lead Time: 6-12 weeks

- Products that involve complex manufacturing processes, advanced technology, or multi-part assembly may require longer lead times.

5. Rush Orders

- Lead Time: 1-2 weeks (with additional fees)

- Some manufacturers offer expedited production for an additional fee. However, this depends on the current production capacity and the nature of the order.

What are the common payment terms when purchasing from China?

Pay 30% in advance and 70% before shipment by T.T. (Standard Products)

Pay 100% in advance by T.T. (Existing Products)

Get started today!

OEM & ODM are both ok,

Find the one that works best for you.

If you need help, we’re here to assist.

Let us know how we can help you, and we’ll be in touch with the information you need to select the best choice.

Contact us today and we will help you winner the order.

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ask For Quote Now!

REPLY WITHIN 24 HOURS

OEM & ODM are welcome.

Find the one that works best for you.